Choosing the suitable coating for your garage floor often involves a comparison between polyaspartic and epoxy. Each type has distinct advantages and challenges, and the ideal choice varies based on individual needs. This expanded guide delves deeper into the specifics of polyaspartic floor coating vs epoxy, aiding in your decision-making process for your garage floor.

Understanding Epoxy and Polyaspartic Coatings

What is Epoxy Coating?

Epoxy, a blend of resin and hardener, forms a solid, enduring surface resistant to chemicals and heavy use. It’s celebrated for resisting stains, enhancing floor aesthetics, and providing a smooth, glossy finish. Due to its resilience and longevity, epoxy is often the go-to choice in commercial and industrial settings.

What is Polyaspartic Coating?

Polyaspartic, a more recent innovation in floor coatings, shares similarities with epoxy but excels in its rapid curing rate. It’s UV resistant, ideal for indoor and outdoor applications, and can be walked on within hours of application. Polyaspartic coatings are known for their flexibility, clarity, and ability to withstand extreme temperatures.

Comparing Epoxy and Polyaspartic

Durability and Protection

Both coatings are highly durable. Epoxy is renowned for its resistance to chemicals, abrasions, and impacts, making it ideal for garages that see heavy-duty use. Polyaspartic offers superior abrasion resistance and is less prone to yellowing over time. It is perfect for high foot traffic areas and spaces exposed to sunlight.

Application and Curing Time

Epoxy’s curing process is more prolonged, typically requiring 24-48 hours, which can be a drawback for time-sensitive projects. Polyaspartic coatings, on the other hand, can set in as little as 4 hours, providing a practical solution for those needing a quick turnaround without sacrificing quality.

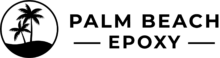

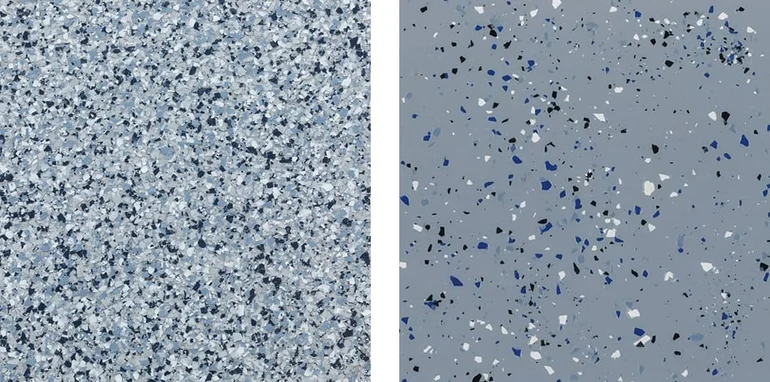

Aesthetic Appeal

Both epoxy and polyaspartic coatings can significantly enhance a garage’s appearance. They are available in a variety of colors and finishes, allowing for extensive customization to match your style preferences. Epoxy tends to have a thicker, glossier finish, while polyaspartic offers a clear, high-gloss look that highlights the underlying concrete’s beauty.

Cost Considerations

Polyaspartic coatings generally have a higher initial cost than epoxy. However, considering their rapid application, curing time, and long-term durability, they may provide more value over time.

DIY Friendliness

The epoxy application requires precision in mixing and a controlled environment to avoid bubbles and imperfections. Polyaspartic coatings, with their more forgiving nature and faster curing time, offer a more user-friendly option for personal projects, especially for those less experienced in floor coating applications.

Environmental Impact

Polyaspartic coatings are a more environmentally friendly option due to their lower VOC content. This makes them preferable in enclosed spaces or areas with limited ventilation. Epoxy, while durable, can emit strong odors during curing and may not be the best choice for environmentally conscious projects.

Maintenance and Longevity

Both coatings are relatively easy to maintain, requiring regular cleaning to retain their appearance. Polyaspartic coatings, however, tend to have a longer lifespan and maintain their appearance better over time due to their superior resistance to UV light and abrasions.

Making the Right Choice for Your Garage

When deciding between polyaspartic vs epoxy for your garage floor, consider factors like your budget, the intended use of the garage, the climate in your area, and how quickly you need the job completed. Both options will significantly enhance the look and functionality of your garage floor, but the right choice will align with your specific needs and circumstances.

FAQs

How long do polyaspartic and epoxy coatings last?

Polyaspartic coatings typically outlast epoxy, often enduring over a decade with proper care. Epoxy, while robust, may require sooner reapplication due to wear and chemical exposure.

Are polyaspartic coatings more expensive than epoxy?

Yes, polyaspartic coatings usually have a higher initial cost. However, their durability and longevity can provide cost benefits over time.

Can I apply these coatings myself?

The epoxy application can be complex, needing accurate mixing. Polyaspartic coatings are more straightforward, making them preferable for DIY projects.

Which coating is better for a garage that gets a lot of sunlight?

Polyaspartic coatings, with their UV resistance, are better suited for sun-exposed areas. The epoxy may discolor or fade under prolonged UV exposure.

How do these coatings handle spills and stains?

Both coatings resist spills and stains effectively. Epoxy excels in chemical resistance and is ideal for garages prone to chemical spills. Polyaspartic coatings are also resistant but excel in abrasion and impact resistance.

Is there a difference in the curing time between polyaspartic and epoxy coatings?

Yes, polyaspartic coatings cure much faster than epoxy, setting within hours compared to epoxy’s 24-48 hour curing time.

Conclusion

Each coating has merits in the epoxy vs polyaspartic showdown, catering to different needs and preferences. By understanding their distinct characteristics, you can select the most suitable option for your garage floor, ensuring both aesthetic appeal and longevity. Whether you choose polyaspartic or epoxy, the key is to ensure that your choice aligns with your long-term needs and expectations for your garage floor.

Both options, when applied correctly, will not only protect and enhance the appearance of your garage floor but also add value to your property. By understanding the unique characteristics and benefits of each option, you can make a decision that ensures your garage floor looks great and functions effectively for years to come.