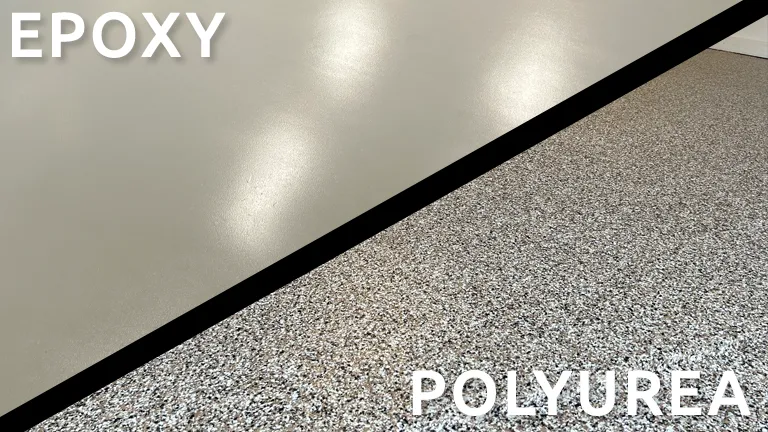

When it comes to choosing the right protective shield for your concrete surfaces, understanding your options is crucial. Two popular choices, polyurea, and epoxy, often lead the pack in discussions about durability and longevity. But which one truly stands out when it comes to enhancing and protecting your space? Let’s dive into a detailed comparison of these two powerhouses in the world of concrete coatings.

Understanding Polyurea and Epoxy

First, let’s break down what these materials are:

- Polyurea: Known for its rubber-like properties, polyurea is a synthetic elastomer derived from a reaction of an isocyanate with a resin blend. This compound is celebrated for its flexibility, robustness, and quick curing time, making it an excellent choice for those who value speed and efficiency in their renovations. It is particularly noted for its performance in harsh environmental conditions, offering excellent water and chemical resistance which can be crucial for areas exposed to such elements.

- Epoxy: A polymer compound formed from epoxides, epoxy is revered for its adhesive qualities and resilience. Comprising a resin and hardener, epoxy coatings create a hard, protective layer over concrete, offering a shield against wear and tear. However, its rigidity can also be a limitation under certain conditions, such as in environments that experience significant temperature fluctuations which can cause the material to crack.

Key Factors to Consider

- Durability and Resistance: Epoxy coatings are durable and resistant to stains, chemicals, and abrasions, making them suitable for indoor environments such as garages and warehouses. However, polyurea outshines with its ability to resist harsher conditions, including fluctuating temperatures and UV radiation, preventing yellowing over time. Moreover, polyurea is less prone to cracking under pressure or impact, which enhances its suitability for high-traffic areas.

- Application and Cure Time: Epoxy might take several days to cure fully, which can be a significant inconvenience. On the other hand, polyurea’s rapid curing time allows floors to be functional within a day, a valuable trait for businesses and homeowners who cannot afford long downtimes. The quick cure rate of polyurea also minimizes the risk of dust, debris, or other contaminants embedding in the coating during the application process.

- Aesthetic and Customization: Both materials offer a range of colors and finishes, with the addition of color flakes to enhance the aesthetic appeal. Polyurea, however, often provides more flexibility in customization, allowing for a greater variety of finishes that can match any décor. This material is also known for its seamless finish, which can significantly enhance the visual appeal of a space.

- Cost Efficiency: While epoxy might seem cost-effective initially, the longevity and reduced maintenance of polyurea could offer better cost efficiency over time. Polyurea might be more of an upfront investment, but its durability means less frequent reapplications, which saves money and effort in the long run.

- Ease of Maintenance: Both coatings are easy to maintain, but polyurea’s superior resistance to chemicals and abrasions means it generally holds up better against the rigors of daily use. This makes it an ideal choice for areas with high traffic or exposure to industrial materials. Polyurea’s resistance to moisture and mildew also makes it a preferable option for environments where these factors are a concern.

Which One Should You Choose?

Choosing between polyurea and epoxy comes down to your specific needs:

- For Lasting Protection: If you’re looking for a solution that offers longevity and robust protection, especially in outdoor settings or in areas with extreme conditions, polyurea is the clear winner. Its superior flexibility and resistance to environmental factors make it a top choice for long-term durability.

- For Budget-Friendly Solutions: If initial cost is a major concern and the application area is less prone to severe conditions, epoxy could be the way to go. Its ease of application and relatively low material cost make it a popular choice for DIY projects and less demanding applications.

- For Quick Turnaround Projects: When time is of the essence, polyurea’s quick curing time makes it ideal for projects that need to be completed quickly without sacrificing quality. This feature is particularly valuable in commercial settings where downtime can affect operations.

Conclusion

Whether you choose polyurea or epoxy, both materials offer significant benefits for concrete coatings. Your choice should align with your specific needs concerning durability, cost, aesthetics, and cure time. Polyurea is renowned for its rapid cure rate and exceptional resilience, making it ideal for high-traffic areas and extreme weather conditions.

On the other hand, epoxy provides a cost-effective solution with substantial protective qualities and a wide range of aesthetic options. It’s essential to weigh the long-term benefits against the initial investment. While polyurea may have a higher upfront cost, its durability and low maintenance requirements can lead to savings over time. Epoxy, although cheaper initially, might require more frequent touch-ups or replacements, especially in harsh environments.

FAQ’s

Can polyurea coatings be applied in colder weather?

Yes, polyurea coatings can be applied in colder weather. Polyurea’s chemical properties allow it to cure properly even at lower temperatures, unlike epoxy, which typically requires a warmer climate to set effectively.

How long do I need to wait before using a newly coated epoxy surface?

For epoxy coatings, it is generally recommended to wait at least 48 to 72 hours before heavy use, such as parking cars or placing heavy equipment. This waiting period ensures the epoxy has fully cured and hardened, providing optimal durability.

Are polyurea coatings environmentally friendly?

Polyurea coatings are considered more environmentally friendly than many traditional coating systems. They emit lower volatile organic compounds (VOCs) during application, which contributes to a safer and cleaner environment.

What makes epoxy coatings susceptible to yellowing?

Epoxy coatings are susceptible to yellowing primarily due to UV exposure. The chemical structure of epoxy breaks down when exposed to sunlight, leading to discoloration. This makes epoxy less suitable for outdoor areas where it will be exposed to direct sunlight.

Can I apply a polyurea coating over an old epoxy coating?

Yes, you can apply a polyurea coating over an old epoxy coating, but proper surface preparation is crucial. The existing epoxy layer must be mechanically abraded or sanded to ensure proper adhesion of the new polyurea coating.

How do I maintain my polyurea-coated concrete surface?

Maintaining a polyurea-coated surface is relatively straightforward. Regular cleaning with mild soap and water is sufficient to keep the surface looking new. Avoid using harsh chemicals or abrasive tools that could damage the coating.